TECHNOSHINE ELECTROPLATING

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TECHNOSHINE ELECTROPLATING

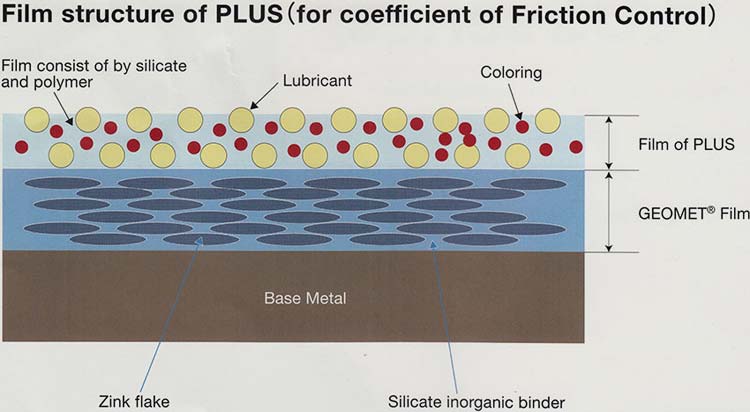

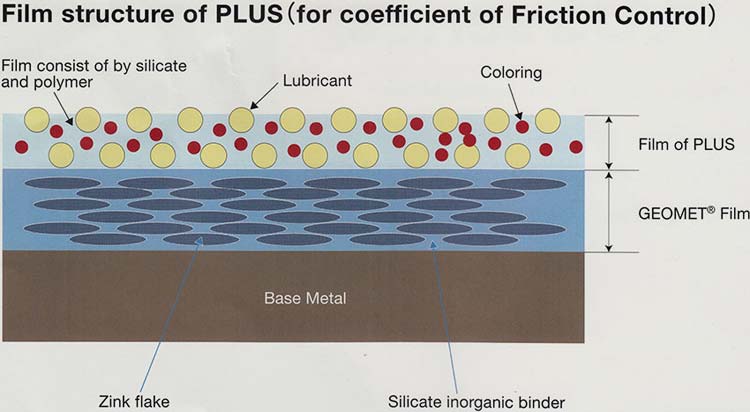

Top Coat

PLUS SERIES

Top coats add new characteristic to GEOMET coatings and improve various coating performance

Realization of consistent friction coefficient. Choose an applicable specification from a qide selection in order to achieve a stable friction coefficient for GEOMET coated.

Improve corrosion resistance of GEOMET Applying GEOMET PLUS series over GEOMET coated will further improve the corrosion and chemical resistance .( Salt Spray Test according to ISO 9227 / ASTM B117 GEOMET®720 + TOP COAT > 1500 hours without red rust)

For beauty of appearance (Black color coating) Meet customer's requirement of black color surface

Improved resistance to galvanic corrosion The GEOMET PLUS series has been used by auto manufacturers as a means of preventing galvanic corrosion on the GEOMET coated metal fittings of robber hoses, such as hose clamps.

The water-based, chromium free coating technology does not cause pollution.

DACROLUB® 10

DACROLUB® 10 is an organic topcoat made from water-based chemicals. This topcoat can be applied to GEOMET® and DACROMET® coatings, whereby the friction coefficient of threaded parts can be reduced and controlled.

Characteristics and performance

Dry lubrication film

Friction coefficient: 0,08 - 0,14 on parts with GEOMET® or DACROMET® measured according to EN ISO 16047

DACROLUB® 10 gives freedom from possible stick-slip problems when tightening (VDA 235-203)

No induced hydrogen embrittlement

Appearance: clear • Salt Spray Test according to ISO 9227 : No effect on the corrosion resistance of the GEOMET® or DACROMET® base-coat

The combination GEOMET® / DACROLUB® 10 or DACROMET® / DACROLUB® 10 is particularly suited to fasteners since it provides them with optimal protection and assembly properties

Being easy to apply, the DACROLUB® 10 can be colored to be used for part identification

GEOKOTE®

Resistance to chemicals and abrasion, improved control of the friction coefficients are requirements increasingly demanded by markets. The combination of the GEOMET® coating with the GEOKOTE® topcoats can respond to new expectations in many industrial sectors.

Characteristics and performance

Strong resistance to hydrochloric, phosphoric, sulfuric acids, automobile fluids and other chemical agents

Stronger resistance to repetitive abrasions

No hydrogen embrittlement

The black, clear or other shades of GEOKOTE® gives freedom from possible stick-slip problems when tightening (VDA 235-203)

The GEOMET® / GEOKOTE® combination is particularly suited to fasteners since it provides them with optimal protection and assembly properties

Salt Spray Test according to ISO 9227 GEOMET® 720 + GEOKOTE® > 150 hours without red rust

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.